The UK quattro Network

The UK's mobile Audi ur-quattro specialist - 07833 654800, 24x7

Rate this page for Google:

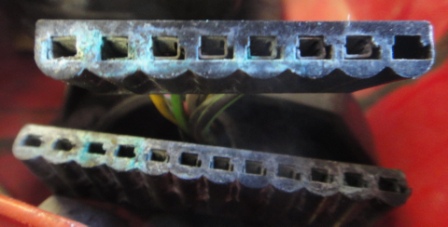

There's no scale to this picture, but the rubbish weighs about 15 grammes. Cars that have stood for five or six years (or more) will often have fuel flow problems when restarted. A good fuel pump running freely should pull about 3 amps or so - a stalled pump can pull as much as 9 or 10 amps. Check the single pole connector under the back seat in the green/yellow line - if it's discoloured start investigating.

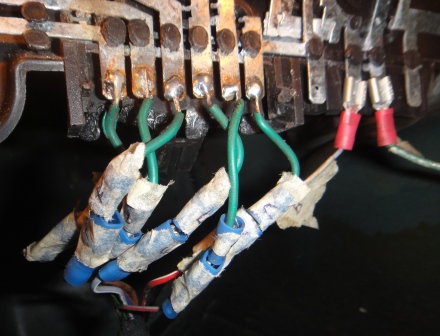

This alarm has been 'disabled', i.e., switched off but the boot wasn't put back properly. It's mounted in the water box just under the windscreen, which is never a good place anyway. But rainwater has done the rest, and corrosion eventually rotted the main power connection to the coil. At first the car stopped intermittently, then permanently.

It's out of a 1989 Audi 100 turbo quattro. And the damage was done by someone else. At 170k miles, it's about time it was changed - lambda probes last around 45k miles under ideal conditions - strange gasket sealants, fuel additives, etc., can dramatically shorten that life. And 10% to 15% is a lot of mileage per gallon at today's prices.

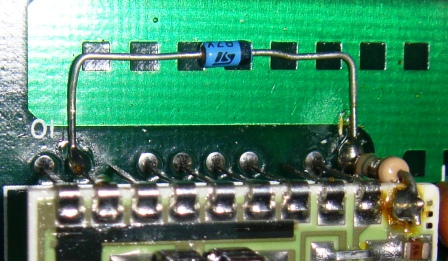

This is out of an otherwise well-maintained ur-quattro 20V - one of the last ones Audi built. The wire is the one from T1u to T6b in track 182 - Audi have fused the circuit at 30A despite 2.5mm wire being rated at only 27.5A instantaneous and around 20A continuous.

On the 10-valves the ECU is mounted directly below this point. And electronics don't like water - especially not in any quantity. In the computer industry it's said that all computers run on smoke - if you let the smoke out, they stop working.

"What on earth is making that tapping noise? We've had the head apart twice." In this case you could actually feel the knock at the distributor, never mind putting a stethoscope on it. The most likely cause is someone replacing and tightening down the camshaft with the distributor still in place.

Care to guess your chances of getting it out? All of the nipples on this car were this bad. Well, apart from the rear right, which had been sheared off so long ago you couldn't see where it had been.

You know you're in trouble when you pull the rear bottom hose off the radiator and nothing comes out - despite the expansion tank being on "Maximum". It's probably Radweld - several cans' worth. Hint - if one can doesn't work, stop trying.

When the book talks about disc thickness, it expects uniform thickness. This was caused by bad guide pins, loose caliper retaining bolts and simple neglect. But I'm convinced we could have sawn logs with it.

Well, it stops the leak. But it doesn't make the valve work, and that's the key problem here. This vehicle had rusted-through rear brake lines, but that didn't really matter since the rear brakes weren't actually being activated anyway. The thick rust on the rear discs would have been a giveaway, if anyone had looked.

Broquet marketing materials contain more bullshit than a Liberal Democrat election manifesto. 'Aligning molecules'? The promised fuel economies are the simple result of the fitting instructions - whoever fits it is enjoined to adjust the car to the leanest mixture it will run with. And it works a treat - with any car with or without a Broquet. Don't forget to listen for pinking and always keep a spare piston or two in stock.

Some of the chipping companies are just a little bit cheeky. This modification to a MAC12 is a simple resistor divider on the output from the manifold pressure sensor to reduce the apparent boost as seen by the ECU's processor by about 30%. The components cost 89p at Maplin's - the previous owner's invoice in the documentation told an interesting story.

This is a classic - the next two pictures are from the same 1991 ur-quattro 20V. The removed release bearing - on the right in the picture - had lost all its grease. The remaining ball bearings could clearly be heard clicking over as it was rotated, but the assembly had long since seized and the pressure plate fingers had started wearing a deep groove on the outer face of the inner race. Bearing failure is normal in ur-quattros and is the major reason for clutch replacement - usually between 120,000 and 150,000 miles. But this car had something less than 30,000 showing on the odometer.

The same supposedly low mileage car as the clutch bearing picture above. Yeah, riiight.

Again the same car - do differential seals go bad in a mere 30,000 miles? People are too trusting - and often buy cars without once looking underneath.

Most ur-quattros were shipped from the factory with constrictor bolts in the fuel injection system. The idea was that the screen would collect any swarf in the system and the reduced aperture (at the other end of the bolt) would limit the engine power so that delivery drivers didn't damage it. The bolt should have been removed during the predelivery inspection - the black museum now contains seven. You don't need to take it out to check - a constrictor bolt has a deep circle engraved in the head. Want an extra few HP?

They're often like this - monkey lads tighten them with air guns and think that's enough. It never is. The pulley (the bit with the teeth) should not be confused with the harmonic damper bolted to it - that is a very expensive item indeed. But the poor little pulley is actually quite cheap, and well worth ordering when planning any timing belt work.

Blank engine numbers can occasionally be legitimate - Audi replaced a number of engines under warranty in the mid-1980s and not all were properly numbered - some do have numbers that are very strange indeed. But that isn't the case here -- this one passed through the hands of someone known to have sold a number of cars with blank engine numbers.

Probably the worst seen so far. Ur-quattro manifolds crack because the engine mount fails, and that usually is a result of the engine mount heatshield rusting away and exposing the mount to the full heat of the turbo and downpipe. So if you want to save a grand or more, spend £17 or so on a new heatshield.

If you're not that good at soldering or reprogramming, there's always the more basic solution. This is a "fishtank" valve, used to limit the boost level seen by the ECU. Once again, a stock of replacement pistons is a good idea.

This is another way to do it - a "fishtank" valve in the wastegate centre chamber line. This time it makes the wastegate lift at higher boost - so you have to fiddle with the ECU a bit. But hanging on to those replacement pistons is a good idea.

On this car, none of the major fuel system components (pre-filter, fuel pump, accumulator, filter) were actually secured to the bodywork. Everything was basically hanging off the fuel lines and kept in place by their grommets. The MoT certificate was a month old.

And a paid invoice in the file, from one of the North's better known Audi main dealers. The turbo filter proved to be an issue, because the oil cooler lines had been fitted across it. Changing a filter shouldn't really take an hour.

This is a Type 44 central locking pump, rescued from under the rear seat of a car with a disconnected battery vent hose. Yes, there is a reason for the battery's fumes being safely led away to the underside of the car.

This one's doubly irritating - not only have our rodent friends stripped the insulation off the wires, but thanks to Audi's odd designs it's actually a redundant piece of the wiring harness that hasn't been deleted but still has power on it. A fuse-blowing machine.

Audi added the hole in the injector cooling shroud (and asked dealers to cut it in older cars) so that some of the forced air would be directed up against the lower surface of the bonnet and thus cool the injector lines, reducing hot weather vapour lock. Someone has come along later, found the hand-cut hole, and conscientiously stopped it up again with a grommet.

It used to be a bolt head - but what would you grab it with now? Oxy-acetylene was tried, and lots of penetrating stuff - but it still sheared.

A nasty surprise when you take off your first bumper. There you are, holding the weight, and there's still another hose clip to undo. And it's the hose clip from hell incarnate. Your Dremel is your friend - replace the clip with a stainless one.

How much sense does it make to change the cam belt (behind the accessory belt) and not change the idler rollers? Well, not a lot, because the car was in pieces again a month later. Was this perhaps one of the monkey lads who thought he'd tapped a continuous source of income by putting back things destined to fail?

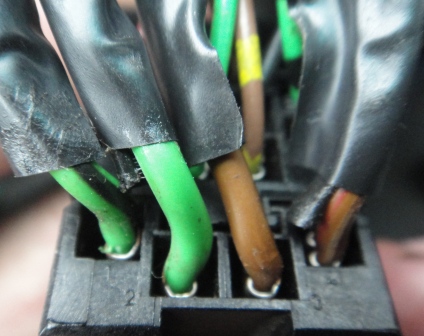

Actually the whole car's "external electrics" were pretty rotten - a good few connectors were salvaged from a spare loom that no one will miss.

It's made the same way salad cream is made - oil and water mixed and whipped. But there shouldn't be any water in the oil, or vice versa. It always seems odd that one car will have water leaking into the oil but no oil in the water, and another will have oil leaking into the water but no water in the oil. Physics knows how, of course, but isn't telling.

An oil fire caused by the turbo oil return line giving way - so check yours. The fire brigade opened the bonnet with a crowbar and put the fire out - the owner later said he wished they hadn't.

The owner had timed this engine up using the harmonic damper mark, and naturally it wouldn't start. This picture was taken with the engine aligned on the flywheel mark and shows just how far the harmonic damper can precess in long term use. It's almost worth knocking the dent on the lower cover flat so it doesn't confuse anyone else.

Rodents are always a problem if a car is left to stand for too long. Normally they infest the engine bay, but these saw the chance of a little more comfort and got out of the cold and draughts. They didn't stop chewing, of course, and so all the seat heater wiring and some of the auxiliary relay panel had to be replaced. Shame about the MoT test audit trail the owner kept in the car though.

Subframe mounting bushes last about 45,000 miles or six years. If the car is stored, or simply neglected, the bolts may not be moved for many years - and when the time comes, they shear. This then becomes an expensive exercise - so it's a good idea just to break and retorque them every few years.

The Bosch ignition system fitted to all ur-quattros is actually pretty fault-tolerant.

It's hard to be sure what's most frightening about this one - the cobwebs, the state of the threaded rod, or the fact that it's here at all. Either way, with the car cutting out because of overboost and the owner having changed the ECU and lost the original eight years before, you know you're in for more than you originally planned for.

This is the back of an early WR ur-quattro loudspeaker fader. And it wasn't just the voice that wasn't working - it took about forty soldered and shrinkwrapped joints to get everything up to an ISO standard.

Good soldering is a matter of cleanliness, the right heat and speed. This is the earth post of a Fuba aerial - the case wouldn't close because of the bulk of the joint so all manner of crud got in.

The lower half-turn of #10 outer valve spring broke off and went for a wander around the inside of the cylinder head, crumbling the walls of several lifters. Amazingly the engine survived - the only external symptom was a slightly strange noise detected using the screwdriver stethoscope. Most of the pieces (the spring was reconstructed) were found in the sump or the oil pickup strainer. A far greater problem in this case was the car - a late 1987 with accelerometer ABS and platinum leather seats on a 1984 V5c. Cough. And HM Fuzz weren't interested.

Is that the cause? Cracks like this - in the left arm of the rear subframe - are much more common in 20Vs than in other quattros. Are they really caused by the Torsen flinging the 20V's torque about as the car is accelerated across wet road markings? And why are they more common in Slough than anywhere else?

Words are sometimes not enough when it comes to false economy. 20mpg is actually not bad when the ignition system is in this sort of state - and lots of people seem to think lambda senders last forever instead of around 35,000 miles. Isn't petrol expensive enough already without wasting 15% to 20% of what you put in?

Not really surprising. And we're still trying to find out exactly what car the front left spring (on the right in the picture) was off - and why it was fitted. It's strange that even the most comprehensive service invoice audit trail never gives you a clue about the funny things that have obviously happened.

The surprise was to find this on an MSA-registered hill climb car. The real problem, as so often with ur-quattro rear lights, was a couple of broken lands in the tail light insert - best fixed as always by screwing a small self-tapper in to short across the break.

Rate this page for Google:

Kerbside Motors Home Page and Contact Information

Contact Phil Payne by email or use mobile/SMS 07833 654800