The UK quattro Network

The UK's mobile Audi 5-cylinder mechanic - 07833 654800, 24x7

Specialist in turbos, quattros, electrics and non-starts

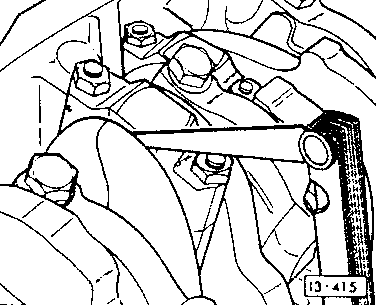

Cylinder bore and conrod clearance

- The engine must not be attached to a stand, e.g., VAG 540 as this can lead to significant distortions

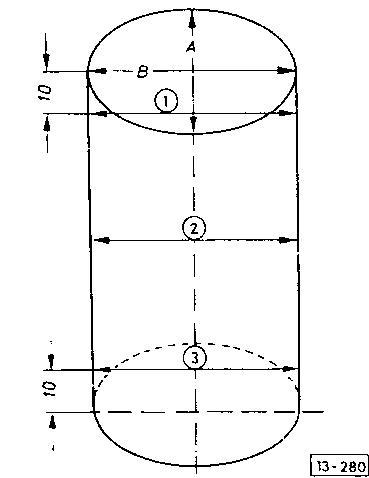

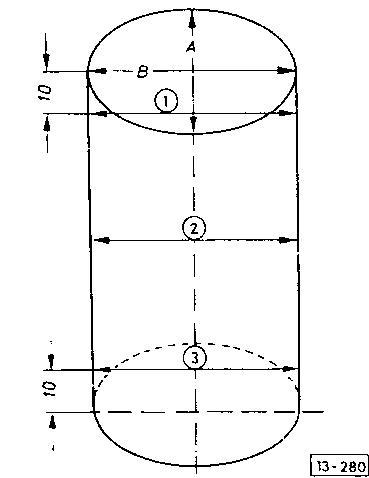

- Measure the bores 10mm from the top (1), half way down the bores (2) and 10mm up from the bottom (3). Make each measurement both longitudinally and transversely.

- Preferred tools are an internal locking micrometer and a digital caliper:

- Collapse the internal micrometer and tighten the gripping screw

- Position the lobes roughly where the measurement is to be made

- Release the gripping screw to allow the lobes to extend

- Position the control stem slightly off-centre

- Tighten the gripping screw until it just grasps the lobes

- Centre the control stem, so that the lobes measure a minimum - the actual diameter

- Tighten the gripping screw to preserve the measurement

- Measure the diameter across the lobes using a digital micrometer

- Make each of the six measurements at least three times and take the averages

- Record the measurements in the service history with the date and recorded mileage

- Measure big end float with standard feeler gauges

- Wear limit is 0.4mm

- Record the measurements in the service history with the date and recorded mileage

Back to index

Next page

Kerbside Motors Home Page and Contact Information