The UK quattro Network

The UK's mobile Audi 5-cylinder mechanic - 07833 654800, 24x7

Specialist in turbos, quattros, electrics and non-starts

Nice to see a quattro (especially one that Kerbside Motors has worked on) appearing as a television star. There's nothing wrong with the standard brakes if you know how to fix them properly. It is a 1983 car though - check out the twin Cibies versus the quad Hellas a real 1981 would have had. Car prepared by Western Automotive

The ur-quattro. The star of the 1980 Geneva Motor Show. The first sports car with permanent all-wheel drive - 0 to 100 km/h in 7.1 seconds. With road-holding untouchable at the time and rarely equalled since. Since then it has become a much-loved classic, though it is now becoming hard to find spares. The rally quattros rewrote the book - today all World Rally Championship cars are four whell drive - and firmly established Audi's slogan: "Vorsprung durch Technik".

This page is a narrative of the ur-quattro's development and its eleven years in production. Another page logs changes at a chassis number level.

The answer to the first question: What does "ur" mean? Well, it's the name of the first city built by man, in (present day Iraq and in Judaic myth the home of Abraham and Sarah. It's used in German to mean "original" - the one from Ur. Back when it was launched, the quattro was the quattro and that was that - but since then so many Audis have been called "quattros" that we call the original the ur-quattro". Germans often refer to them as "uris". Audi stealership parts people are fond of asking: "Yes, but what sort of a quattro - an Audi 80, 90, 100, A4?". "NO!," you scream," a real quattro!"

It all started in February 1977 when Ferdinand Piech - Audi's Director of Technical Development - was contacted by his chassis engineer Jörg Bensinger. Bensinger had been in Finland with Volkswagen's four wheel drive Iltis - developed for the Germany Army and for forestry. It ruled supreme in the snow - no other vehicle in the tests could touch it. Bensinger's idea was to start developing an Audi 80 variant in co-operation with Walther Treser, Director of Pre-Development.

The test car was a red two-door Audi 80 with the code name A1 - "Allrad 1" and the registration IN - NC 92. Hans Nedvidek designed a transmission very similar to the Iltis' - no centre differential.

In September 1977 Project A1 - until then unbudgeted - received the go-ahead from Audi's board and was renumbered EA 262 - "Entwicklungsarbeit 262".

Audi needed the approval of VW's board to continue to marketing, so a test took place at the Turracher Höhe in January 1978. This is the steepest and one of the highest roads in Europe - over a 30% gradient in places - and an ideal place for snow testing.

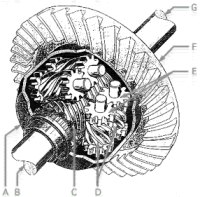

Afterwards Professor Ernst Fiala, the VW Group's Development Director, let his wife borrow the prototype for a shopping trip in Vienna. Her complaints about the car "hopping" and being hard to park led to a centre differential being demanded. This resulted in a brilliant idea credited to Hans Nedvidek and Franz Tengler - driving another Audi 80 differential placed longitudinally via a hollow propshaft. Engineers accustomed to other 4WD systems often lie on their backs under ur-quattros, lost in admiration at the simplicity. After a short final test, the production go-ahead was given.

On 3rd March 1980, at the Geneva Motor Show, the ex-factory price was to be an eye-watering DM49,900. For comparison, the Coupe GT built on the same shell (and sharing the "85" chassis code) cost around DM20,000. The differences were permanent all-wheel drive, fuel-injected 160 bhp turbo engine (very soon increased to 200bhp), Audi 200 brakes, 2 extra lockable differentials, and an awful lot more fun.

Most show cars are never actually built. But the Audi quattro was built, and the first of over 11,000 lucky owners had their cars in November that year. ur-Quattros were built in Hall N2 at Audi's Ingolstadt factory. But not on a production line - every car was hand built right to the end. Although Audi's other production lines operated 24 hours a day and seven days a week, Hall N2 had a single shift of twenty working from 06:00 to 14:00, weekdays only. At its peak, including the janitor and the tea-lady, the whole team numbered 48. Each quattro took seven days and 40 hours of labour to build - with roughly three a day leaving Hall N2. Once completed, each vehicle went through a test programme that is still the strictest Audi has ever used. The engine went through its own test cycle, and the suspension was electronically checked. Then it was run up to 160km/h on a test stand and driven for 60km on public roads around Ingolstadt - first on ordinary roads and then on the Autobahn, with a rev limit of 4000rpm or 185km/h. Then it went around an Audi test track to check the suspension. On each trip two stops were made to check fluid levels. Any test vehicle involved in an accident was immediately scrapped, with components being recycled into later production. Finally a rain test showered the car with 3500 litres of water for ten minutes - other Audis faced the same test for only 30 seconds. Until recently the only comparable programme today is the construction of the Porsche Carrera GT in Leipzig, but Audi has now returned to the fray with the R8.

The ur-quattro was the first high-performance production vehicle to use electronic engine management - though the system was pretty crude by Audi's current standards. Well, it was nearly three decades ago. The computer (ECU) could "see" only boost levels, inlet air temperature and crank position - a set of internal maps then generated timing information, but there was no feedback on their success. Sadly, the absolutely brilliant Philips MCC was never fitted and a rather boring Blaupunkt Toronto SQR radio was chosen for the export market. Goodyear 205/60 HR 15 tyres were standard, on 6J 15" Ronal rims. As an option, 205/55 HR 15s were available on 7J 15" Fuchs rims. These were also used on the rally cars for gravel stages. Power steering, hydraulically assisted brakes, headlight washers, front and rear fog lights and a tinted windscreen were also standard. The wiring diagram was a mere eight pages. And hand-written. In German. Bavarian German.

In March 1981 the quattro came onto the UK market. Initial plans were for 200 to 300 sales, but in fact only 163 vehicles were shipped. This was perhaps a disappointing start in what was later to be Audi's best export market - but let's not forget they were still all left-hand drive. The first chassis officially shipped to the UK was 85-B-900099. Very soon afterwards, the cam and combustion chambers were revised. Electric windows and central locking were fitted to all cars - six UK Audi dealers were defined as centres of excellence and each was provided with special training and a demonstration car. Although Audi had claimed that conversion to right hand drive was impossible, a number were indeed so converted - the best of the conversions being done by David Sutton's team. On the 22nd October 1982 Audi announced that it would build the quattro in right-hand drive form - the first official RHD quattro being 85-D-900556. The brakes were still on the left (and stayed there during the quattro's life) worked by a long pushrod running behind the heater from the driver's pedal.

For the 1983 Model Year (starting in August 1982) there was a small revision to the lighting. The quad headlights fell victim to new one-piece Cibie headlights with integrated driving lights - a vast improvement in the light thrown on the road. Although the quad headlights looked distinctive, they weren't up to high-speed cruising at night. Because Audi's headlight switches are notoriously weak and the battery is behind the passenger, many owners fitted extra wiring harnesses to reduce the load on the switch and provide more volts to the lights - this is perhaps the most common modification made by owners.

Drop-links were added to the front anti-roll bar mountings to reduce noise transmission to the body, and the rear anti-roll bar was omitted from a new rear suspension. This improved straight line stability and reduced sensitivity to crosswinds. Worthy of note - the ur-quattro uses wishbones and MacPherson struts all round - the rear suspension is a front suspension installed backwards.

The 1983 Model Year also saw the ur-quattro going to North America. A large batch of cars was prepared in advance of approval - these cars are the most idiosyncratic of all the ur-quattros, despite the entire production being hand-built.

In April of the 1983 Model Year a new green digital dashboard entered service. An autocheck unit with a voice synthesiser was added. She's called 'Patrizia' and proper manners require her to be replied to - "Please refuel" should be greeted with "As soon as I can, Patrizia".

Model Year 1984 saw the Audi 200's leather steering wheel make an appearance and the dashboard was revised. A three-channel ABS system controlling the front wheels separately and the rear wheels as a unit - earlier an option - became standard, though the driver could switch it off for soft snow conditions. It was automatically disabled if the differential locks were engaged. And UK drivers now found the windscreen wipers on the correct side.

The suspension was significantly modified in March 1984 - new springs and shock absorbers lowered the car by 20mm. The standard tyres were changed to 8" (up from 6") Pirelli P700 215/50 VRs on Ronal rims. This was a story in itself - it turned out that the ur-quattro was not being built according to the drawings. Very un-German. In theory, the 8" tyres shouldn't have fitted. Audi did the unexpected and changed the drawings rather than the car, although the wings had to be modified slightly to accomodate the new tyres.

The Sport quattro was being built around this time, though the major part of the effort took place at BAUR Karosserie- und Fahrzeugbau GmbH in Stuttgart-Untertürkheim and not in Audi Ingolstadt - there will one day be a separate page for BAUR and the Sport on this site. At around four times the price of even the relatively expensive quattro, the Sport was going to be rare. BAUR was bought out by IVM München in 1999 and is still at it, producing design studies for Audi (the A8 Coupe shown in Geneva) and raw body shells for the Porsche 959 and the BMW Z1. And pressing new wings for ur-quattros.

For the 1985 Model Year, the quattro received its only significant external facelift. The vertical front grill was replaced with a sloping one with sloping headlights, slightly improving the CW value and the top speed, and helping the headlights stay clean. Smoked tailights were fitted, though the originals only had one twin-filament bulb per side for the brake and sidelights. Later on, a second would be added each side to meet TüV requirements. The rear spoiler was painted in the body colour rather than black - the Audi logo and the quattro label on the boot were badges and not transfers as before. The seat heater switch was replaced with separate thermostatic controls for driver and passenger. The price had risen to DM75,920.

Starting from the end of 1985, the differential lock switch was changed from a pull type to a rotary type - the space regained behind the centre console was used for LED graphical displays of battery voltage and oil temperature.

Another little goodie appeared at the end of 1986 - gas-filled struts were fitted to the bonnet, making fluid level checking much easier.

Early in the 1987 Model Year came one of Audi's quieter changes - invisible unless you look under the rear seat. A longitudinal accelerometer was added to the ABS system, providing a fifth input about vehicle motion to the controller. In theory, it was possible to lock the wheels with the previous system if they all locked simultaneously - because the controller would have no way of knowing that the vehicle was still in motion. The accelerometer (actually a mercury motion detector) solved that problem, as its transverse cousin had earlier solved the same problem on the Sport quattro.

A major change occured with the 1988 Model Year - the 2144cc solid lifter engine that had powered the quattro since its launch was replaced with a 2226cc hydraulic lifter successor. This engine and its electronic controls were derived from the first version of the MC engine used in the Audi 5000 marketed in North America and designed to meet ever more stringent emission standards. The compression ratio was raised from 7:1 to 8.6:1. The engine management system was adapted from the North American car by deleting the logic for the lambda sender - but the fueling algorithm was retained, making the MB-engined ur-quattro and its Audi 200 avatar with the 1B engine unique among all cars (Audi or not) in their use of electronic fueling with a dependence on assumptions of engine volumetric efficiency.

Whereas the earlier cars only had electronic ignition timing control, the MB's ECU controlled timing, boost and fueling. A knock sensor was added to provide some feedback on the timing. The maximum speed rose to 222 km/h, with 0-100kph now coming in 6.7 seconds - thanks partly to electronic wastegate control. The front brakes had to be upgraded to meet German TüV regulations - twin-piston calipers were fitted and the master cylinder was enlarged. The hydraulic assist system was completely revised with a separate high-pressure circuit from the pump, real hydraulic oil, and the pressure regulator integrated into the hydraulic fluid reservoir.

The transmission was completely overhauled for the MB engine - the centre open differential was replaced with a TORSEN torque-sensing differential using Xyzel gearing manufactured under a Gleason patent requiring a completely different driving style. Only the rear differential could now be locked - doing so also disabled the ABS system. The differential lock was speed-sensitive, automatically disengaging (and re-engaging the ABS) at 20kph. Seat heaters were standard. The dashboard was changed - it became orange (a colour favoured by submariners operating at night) and the odometer became fully electronic. The boost gauge disappeared, in part because it was useless anyway but also because the same dashboard was used on the 1986 North American non-turbo Coupe GT - it was replaced by a water temperature gauge that also functioned (to the confusion of many drivers on left-hand bends) as a coolant level warning device. The voice synthesiser was deleted - some functionality moved to the new digital display, and some (like the seatbelt warning, which was only ever on the driver's seat) simply disappeared. Along the way, the tilting roof had become standard, though full tilt-and-slide was still impossible because of the roll bar in the roof. Chrome Audi rings and emblems on the (now fibreglass) boot lid completed the changes.

The MB was the rarest of all the ur-quattros, disproportionately popular in the UK because of the climate and the TORSEN centre differential, and the 1989 MB was one of the the rarest Audis of all - only around 120 were built in total.

In July 1989 the MB engine was replaced by the 20-valve RR engine - a move made necessary by the discontinuance of the 10-valve engines in a quest for ever lower emission values across the Audi range. The 20V cross-flow engine had new Bosch Motronic control, two catalytic converters and a compression ratio increased to 9.3:1 - 220bhp. Previous ur-quattro engine management systems had been proprietary - manufactured by Hitach to special order. The Bosch Motronic is an industry-standard component - skills, modifications and tuning are much more readily available. The cats were never a legal requirement in the UK and many have been removed to invigorate the 20V's otherwise slightly lifeless exhaust note. The most obvious change seen by the driver is the low-end torque - an amazing 309 Nm at only 1950 rpm, making the 20V the most tractable of all the ur-quattros. And, for a sports car, a quite incredible towing vehicle. But a race car, jet-ski or a hydroplane, please - not a caravan or horsebox. The 0-100 kmh time was reduced to 5.9 seconds and the maximum speed slightly increased to 230 kmh. Again, German TüV regulations required a brake upgrade to match the increased power - the rear disks were now ventilated. Drivability was improved and the fuel consumption (lower emissions being the main reason for the 20V engine's development) was slightly reduced. The interior (described elsewhere) was a little special - the word "quattro" was Jaquard woven into the seat fabric and a new three-spoke steering wheel (which has its detractors) was fitted. The carpets were made from the same material later used in the flagship V8. With the consolidation of many "optional" features that had become standard in the intervening years, the wiring diagram - excluding extra features - was now a massive 21 pages.

In the meantime the price had climbed to DM96,200 - £32,000, or £43,500 at 2003 values. So it's easy to understand why only just over 1,000 20Vs were built. It was to be the last of this certainly exceptional range - and the very last of all left the production hall on 17 May 1991, straight into an Audi museum.

Audi had cut the price for the quattro feature on its other cars in March 1989 - only the ur-quattro's price continued to climb. Even at this point Audi wanted to discontinue the quattro, but there were too many orders outstanding. This gradually came to an end with the S2 having the same engine but being DM16,000 cheaper. The S2 replaced the ur-quattro in Audi's product range, but never had the flair and presence of a real ur-quattro - not least because it had no competitive success behind it - even though it competed in rallies and in tarmac races. Even its production line manufacture differed from the ur-quattro, which was hand-built throughout its eleven years of production by a volume car manufacturer and was years ahead of of its time.

And overall - Audi has used quattro drivetrains in well over two million passenger cars. But the ur-quattro led the way.

Want to know more? Click here

Notes:

Kerbside Motors Home Page and Contact Information

Contact Phil Payne by email or use mobile/SMS 07833 654800