The UK quattro Network

The UK's mobile Audi 5-cylinder mechanic - 07833 654800, 24x7

Specialist in turbos, quattros, electrics and non-starts

MAC01 WR ECU General Description

(Much of this information also applies to the MAC02 used in the North American,

Swedish and Swiss WX cars, although the emission control logic is not dealt with.)

The official factory fault-finding table for the WR engine will be found in the Workshop Manual.

For the moment, most of the electrical tests are better documented here. Links have been added to each test pointing back to the Workshop Manual pages - for the most part, these links are not yet functional.

The electronic ignition system fitted to the early Audi ur-quattro is known as a "Hartig" system after its inventor because it uses a tooth-sensing sender (U.S. Patent 4,121,112 - October 1978). The MAC01 Electronic Control Unit (ECU) uses six inputs:

- Engine RPM sender (G28) on upper surface of clutch bell housing, reading passing flywheel teeth.

- Timing point (TDC) sender (G4) left lower side of clutch bell housing, reading a pin on the front surface of the flywheel

- Inlet air temperature sender (G42) on top of inlet manifold

- Hall effect sender (G40) on side of distributor

- Inlet manifold pressure sensor - built in to ECU

- The idle switch on the throttle body. This is the lower of the two switches and should have brown/blue and brown/yellow wires attached underneath the switch. It is normally open but held shut with the throttle in the rest position. The upper switch should have black/blue and black green wires attached to the side of the switch using flag-type connectors. It is normally closed but opens at 55° throttle opening.

There are three outputs:

- An ignition pulse, amplified by the ignition output stage (N41) and applied to the coil to cause combustion. This is referred to as the "activation signal" in the diagram below.

- A fuel pump control signal. This signal is applied to the fuel pump relay (J17) once engine RPM reaches a preset limit and is cut if the engine stops (fire prevention in event of an accident), the programmed maximum boost levels are exceeded (to prevent engine damage) or the engine rpm exceeds a safe limit. The WR's fuel pump relay is in position 10 of the under-bonnet fuse box on later cars and may be 857 951 253 or 191 906 383C - blue with "67" on the cap. Recently, Audi has started shipping a black version of 191 906 383C with no top code; this is acceptable. A fuel pump relay with "Kraftstoffpumpenrelais mit Drehzahlbegrenzung" on the side will cause performance problems.

- An analogue signal derived from the inlet manifold pressure is applied to the ignition output stage up to model year 1982 and to the digital dashboard from model year 1983 to model year 1987.

The MAC01's only way of influencing engine performance is by varying the engine's timing. There is no provision for ECU control of the cold start valve, mixture, boost level, airflow or deceleration cut-off. The MAC01 controls idle stabilization between 600 RPM and 940 RPM using advance/retard only. This means conventional timing analyzers, strobe lights, etc., cannot be used.

Because there is no physical compensation in the distributor - no vacuum-controlled platform or centrifugal weights - it is imperative that the rotor arm has a wide enough tip to accommodate spark transfer over a significant advance/retard angle. The stock rotor arm is specific to the WR application - using a generic part with a narrower tip can cause performance problems at high boost and RPM levels. The rotor arm has a tendency to crack near the tip and should have a resistance of 1k Ohm

Ignition coil primary current is regulated to 7.4 amperes. With the ignition on and the engine not rotating, this current is interrupted after 1 second to prevent the coil overheating. Only original Audi ignition coils should be used - the primary resistance and the 5.5 mm safety valve opening are unique to the WR/WX ur-quattro. Nominal coil resistances (with all plugs disconnected):

- Pin 1 (-) to 4 (HT output) 2.4k ohm to 3.5k Ohm

- Pin 1 (-) to 15 (+) 0.52 to 0.76 Ohm

Fundamentals of Operation

There are more exhaustive texts elsewhere, but the basics of starting and operating are as follows:

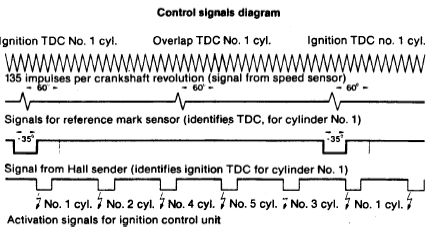

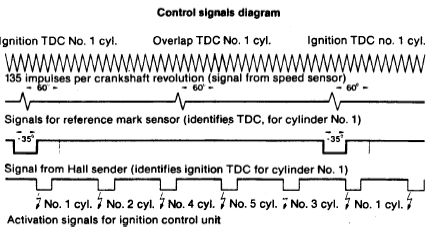

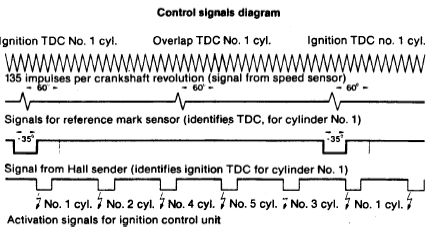

- When the ignition is turned on, the MAC01's embedded computer performs a power-on self-test and sits in a spin loop watching for pulses from G28, the flywheel tooth sender. This is referred to in the above diagram as the "speed sensor" and is represented by the sawtooth waveform in the top line of the diagram.

- When it sees pulses from G28, it starts to look for a pulse from G4, the reference mark or TDC sender - this is represented by the second line in the diagram.

- When it sees a pulse from G4 - the reference mark sender - the engine is in one of two positions:

- TDC #1 cylinder - compression/firing stroke. In this case, the Hall window (G40) represented by the third line of the diagram will be "open"

- TDC #1 cylinder - exhaust/induction stroke. In this case, the Hall window will be closed.

- The ECU waits for the first situation and then counts teeth.

- If all is well, the ECU will trigger a spark on the next and all subsequent TDCs, timing each cylinder by counting flywheel teeth to know the flywheel position and applying its calculated advance/retard delta. Although the diagram appears to show the first activation signal to the ignition control unit occurring exactly when the Hall window closes, this is a coincidence - the signal is timed from the reference mark or TDC sender and varies significantly with rpm, inlet air temperature and boost level.

- If the ECU is not satisfied with its inputs, it will fire #1 cylinder erratically to demonstrate that the output stage and coil are in working order - this is called a "wasted" or "maverick" spark.

MAC01 WR ECU Diagnostics and Tests

Before all tests - especially in no-start conditions - the mechanical timing of the engine should be checked:

- Flywheel '0' mark bisected by protrusion in bell housing window - critical.

- Rear of cam pulley mark set to top of cam cover gasket - +/- one tooth.

- Scribed line on Hall effect rotor (or exact centre of rotor arm tip, if no scribed line can be seen) aligned with nick in distributor wall - critical.

The harmonic damper (crankshaft pulley) has no useful marks. The scribed line on the flywheel is for use on other engines.

The WR's ECU is mounted in the plastic trim underneath the right hand side of the dashboard. On LHD cars, it is necessary to remove the glove box. On RHD cars, the trim underneath the steering wheel is secured by three screws at the front going up into the dashboard and a single screw at the very back of the driver's stowage compartment - a torch or flashlight is essential.

The most common ECU problem so far met is inlet boost pressure sensor failure caused by fuel contamination; this causes poor starting, uneven running and erratic behaviour during acceleration - although even this is rare. The primary cause seems to be the last section of rubber hose before the ECU - after the fuel trap - going porous. It is worthwhile replacing this hose during any test procedure. There is an official test procedure for the pressure sensor - a VAG 1367 is attached to measure the timing point - it should advance from around 6° (before VIN 85-B-901 297) or 12° (85-B-901 297 or after) to over 20° if the hose is pulled off the ECU with the engine idling. Electronic failure is extremely rare - only one case of a cracked PCB board (already the subject of a repair at some time in the past) has so far been seen.

As above, it is important to distinguish between 'no spark' and 'maverick spark'. For this purpose, either a Gunson spark cell can be inserted in #1 plug lead or #1 plug can be removed and tie-wrapped to the lifting eye above the hydraulic pump. If no spark at all is ever seen, classic electrical failure in the ignition circuit may be suspected. If an occasional maverick spark is seen, the ECU is receiving either no or incorrect information from one of its sensors. If all of the documented tests are passed, it may be necessary to try the ECU in a known good car. This is preferable to putting a known good ECU in a car that may have destroyed one already. There are no specific ECU-related output diagnostic tests.

If start testing is prolonged, be aware that the cold start injector will spray a small amount of fuel into the engine at each start attempt. This can result, over time, in a significant amount of fuel contaminating the oil requiring an oil change during testing. Monitor the oil level throughout these tests.

MAC01 WR ECU Pin-out and Cable Colours

With the ECU removed from the car and the connector held with the engaging hook on the left and the locking tang on the right, the connector pins are numbered 1 - 13 from right to left on the bottom row, and 14 - 25 from right to left on the upper row. In-car measurements with the ECU in place require the cover to be removed from the connector and pushed back up the harness - the pin can then be identified easily via its wire colour as per the table above.

| Pin | Colour | Function | Test |

|---|

| 1 | Brown | Ground |

| 2 | Brown/white | Ignition output stage (1980-2)

Dashboard boost gauge (1983-7) | 28-51

None |

| 3 | Brown/blue | Idle switch | 28-35 |

| 4 | Brown/red | Hall sender ground return | 28-41 |

| 5 |

| 6 |

| 7 | Purple | RPM to oil pressure controller & dashboard |

| 8 |

| 9 |

| 10 |

| 11 | Yellow | RPM Sensor signal | 28-20 |

| 12 | Yellow | TDC Sensor signal | 28-16 |

| 13 | Black | TDC Sensor signal | 28-16 |

| 14 | Black | Terminal 15 Ignition +12V |

| 15 | Brown/yellow | Idle Switch | 28-35 |

| 16 | Green/purple | Fuel Pump Relay control |

| 17 | Green/white | Ignition output stage | 28-51 |

| 18 | Red | Intake air temp sensor | 28-25 |

| 19 | Red | Intake air temp sensor | 28-25 |

| 20 | Red/black | Hall Sender + 12V | 28-41 |

| 21 |

| 22 | Green | Hall Sender timing signal | 28-41 |

| 23 | | RPM sensor shield ground | 28-20 |

| 24 | Black | RPM Sensor signal | 28-20 |

| 25 | | TDC Sensor Shield ground | 28-16 |

Spare pins for the connector are available from Audi as part number 000 979 225A - this is actually a wire with a new pin connected to each end as few garages possess the correct crimper. The repair is thus a butt splice to one of these wires cut in half. Old pins can be released with a dressmaker's pin pushed down outside each flat of the pin from the face of the connector to release the tangs.

MAC01 WR ECU Diagnostic Tests

28-16 TDC (G4) Sender Test

G4 is located half-way down the engine/bell housing union on the left, below the brake accumulator. The connector is identical to that for G28 - after performing the following resistance test, trace the wire back from G4, detach the connector and repeat the test to check for open circuit.

- Unscrew and slide out the sender.

- Using a multi-meter with resistance and a/c millivolt scales, check that the centre pin has a resistance of ca. 1k Ohms to one of the outer pins. The other pin is not connected.

- Switch the multimeter to the millivolt scale and wave the sender close to a metal object such as a screwdriver or wrench. The meter should react - if not, replace the sender.

- Detach ECU connector

- Check resistance between ECU connector pins 12 and 13 for ca. 1k ohm. If bad, continue:

- Disconnect engine bay connector for TDC sender. With clip uppermost, check for continuity between the right contact and ECU connector pin 13. If bad, repair loom.

- Check continuity between centre contact and ECU connector pin 12. If bad, repair loom.

- Check continuity between left contact and ECU connector pin 25. If bad, repair loom.

- Check resistance between ECU connector pins 12 and 25. If not infinite, repair loom.

- Check resistance between ECU connector pins 13 and 25. If not infinite, repair loom.

- If all wiring tests passed, remove starter motor and rotate engine slowly to check the flywheel signal pin is intact and unbent.

A sheared-off and a slightly bent flywheel pin

- If all tests passed, replace TDC sender.

28-20 RPM (G28) Sender Test

- Unscrew and slide out the sender.

- Using a multi-meter with resistance and a/c millivolt scales, check that the centre pin has a resistance of ca. 1k Ohms to one of the outer pins. The other pin is not connected.

- Switch the multimeter to the millivolt scale and wave the sender close to a metal object such as a screwdriver or wrench. The meter should react - if not, replace the sender.

- Detach ECU connector.

- Check resistance between ECU pins connector 11 and 24 for ca. 1k ohm. If bad, proceed:

- Disconnect engine bay connector for RPM sender. With clip uppermost, check for continuity between the right contact and ECU connector pin 24. If bad, repair loom.

- Check continuity between centre contact and ECU connector pin 11. If bad, repair loom.

- Check continuity between left contact and ECU connector pin 23. If bad, repair loom.

- Check resistance between ECU connector pins 11 and 23. If not infinite, repair loom.

- Check resistance between ECU connector pins 23 and 24. If not infinite, repair loom.

- If all wiring tests passed, check the flywheel teeth. The best way is to remove the starter motor and rotate the engine slowly - this also allows the timing pin to be examined.

- If all tests are passed, replace RPM sender.

28-25 Inlet Air Temperature Sender Test

The following is valid up to 85-B-901140. From 85-B-901141 onwards the connections on the inlet air temperature sender are soldered. Up to 85-B-901344 the connector was retained, but moved to the wheel housing. Later vehicles have no connectors, but the tests are the same.

- Peel back the boot over the inlet air temperature sender's connectors and check the connections.

- With the ignition off, check the resistance between the sender's connectors for between 13 and 33 ohms. Deviation from around 21 ohms is uncommon.

- Detach ECU connector.

- Check resistance between ECU connector pins 18 and 19 for 13 to 33 ohms. If bad, proceed:

- Disconnect connector from inlet air temperature sender on top of inlet manifold. With clip uppermost, check for continuity between the left contact and ECU connector pin 18. If bad, repair loom.

- Check continuity between right contact and ECU connector pin 19. If bad, repair loom.

- If all wiring tests passed, replace inlet air temperature sender.

The connections to the sensor itself are soldered and are notoriously unreliable. It is worth replacing the soldered connections with crimped ones:

- Desolder the wires.

- Remove the air temperature sender from the inlet manifold.

- With GOOD non-bevelled side cutters, lift the spot-welded contacts away from the sensor's tangs.

- Clean up the tangs with a flat jeweller's file.

- Crimp 3mm female spade connectors (used for loudspeaker connections - see car audio dealers) onto the wires.

- Replace - noting that excessive torque easily damages the sensor.

28-35 Idle Switch Test

Consolidates changes from Technical Bulletin D 000.5147.01.00 (TSB)

- The idle switch is the lower of the two microswitches operated by the throttle quadrant. The upper switch is the full load (WoT) switch. The connectors are interchangeable - ensure that the brown/blue and brown/yellow wires go to the lower switch.

- [TSB] Pull both connectors off the idle switch.

- [TSB] Connect an ohmmeter to the contacts.

- [TSB] With the throttle closed, value should be zero ohms.

- [TSB] With the throttle open, value should be infinite.

- [TSB] Check resistance between brown/black wire and chassis ground - zero ohms

(Audi's TSB is wrong - there is no brown/black wire. The closest is the brown/blue that returns to ECU pin 3)

- Detach ECU connector

- With the throttle closed, check for closed circuit between ECU connector pins 3 and 15. Open the throttle a few degrees and check for open circuit. If bad, proceed:

- Detach both connectors from the idle and full throttle switches on the throttle body.

- Check continuity between the idle switch brown/blue wire and ECU connector pin 3. If bad, repair loom.

- Check continuity between the idle switch brown/yellow wire and ECU connector pin 15. If bad, repair loom.

- If all wiring tests passed, replace idle switch, adjusting for operation by closing throttle valve at 1° to 2.5° from rest.

Note that there is no specific full load switch test defined because it is not connected to the ECU in the WR ur-quattro. With the ignition on, +12V should appear at the black/blue wire on the throttle body switch. The black/green wire should have continuity to the solenoid valve on the bulkhead, and the other wire from that connector should go to chassis ground. Opening the throttle by 50° to 55° should open the full load switch and cause the solenoid valve mounted on the bulkhead to de-energise with an audible click. This operation is best verified by attaching a MityVac and applying vacuum before operating the switch - see the discussion of the WR's full load enrichment in the mechanical pages. The thermopneumatic valve (left rear edge of the head) plays an important role in full load enrichment - it should be open up to 58°C +/-3°C and closed at higher temperatures.

28-41 Hall (G40) Sender Test

- Check for correct wiring of the Hall sender connector. Brown/white to pin 1 (-), green to pin 2 (0) and red/black to pin 3 (+). Check physical state of both connectors.

- Attach ECU connector if disconnected.

- With ignition on, check for 10V or more between pins 1 and 3. If bad, repair loom.

- Detach ECU connector.

- Check continuity between ECU connector pin 20 and Hall sender connector pin (+). If bad, repair loom.

- Check continuity between ECU connector pin 4 and Hall sender connector pin (-). If bad, repair loom.

- Check continuity between ECU connector pin 22 and Hall sender connector pin (0). If bad, repair loom.

- Turn the crankshaft until the window in the distributor screen is in the Hall sender gap, i.e., there is no metal between the black plastic parts of the Hall sender inside the distributor.

- Remove the cover from the ECU connector and slide it back along the cable.

- Replace the ECU connector.

- Attach a voltmeter between ECU pins 4 and 22.

- Switch on the ignition - voltage should be 0V to 0.5V.

- Switch off the ignition. Turn the crankshaft so that the distributor screen is in the Hall sender gap, i.e., the inner black plastic part of the Hall sender is no longer visible.

- Switch on the ignition - voltage should be > 4.0V.

- If any voltage outside specifications, replace distributor.

28-51 Ignition Output Stage (TSZ) Test

- Attach ECU connector if detached.

- Connect a voltmeter across the coil low voltage terminals 1 and 15. Operate the starter and check for ca. 1.2 volts.

- Detach connector from ignition output stage - N41 - bolted to underside of waterbox, directly above ECU.

- Connect a voltmeter between pins 2 and 4 - check for battery voltage.

- Detach connector from coil pin 1 and check continuity to ignition output stage connector pin 1.

- Check continuity between output stage connector pin 2 and chassis ground. If bad, repair loom.

- Detach connector from coil pin 15 and check continuity to ignition output stage connector pin 4. If bad, repair loom.

- Detach ECU connector.

- For 1980-2 vehicles ONLY check for continuity between ECU connector pin 2 and ignition output stage connector pin 3. If bad, repair loom. Ignition output stage connector pin 3 is not connected to anything on 1983-7 vehicles - ECU connector pin 2 is connected instead to the digital dashboard boost gauge.

- Check continuity between the ignition output stage connector pin 6 and ECU connector pin 17. If bad, repair loom.

- If all wiring tests passed, replace ignition output stage.

MAC01 WR ECU "Chipping"

The easiest way to increase WR performance is to hot-wire (or "jumper") the fuel pump so that it always runs with the ignition on, and then replace the spring in the wastegate with a stiffer one.

This is DANGEROUS for two reasons:

- The ECU is designed to cut the fuel pump if boost levels exceed the design maxima. This does not merely occur when a stiffer spring is fitted, but also if the wastegate control hose splits or becomes blocked at the manifold end, or if the wastegate diaphragm tears. Overriding the feature in this instance may lead to bodywork damage caused by flying bits of engine.

- The ECU will also cut the fuel pump if it cannot see engine rotation. This is an important safety feature - in a serious frontal accident the engine will usually stop and the last thing anyone needs is ca. 2.5 litres of fuel per minute being pumped enthusiastically into the (hot) engine bay.

The MAC01 ECU is sometimes modified by "chip tuners" to permit higher boost levels than stock while retaining the "dead engine" cutout feature. The most common modification is via a resistor/Zener diode bridge on the manifold pressure sensor output. A 4.3v Zener diode is soldered across pins 1 and 5 of the manifold pressure sensor daughter board - marked end to pin 1 - and the connection between pin 1 and the motherboard is replaced by a 470 ohm resistor. Unscrupulous tuners have been known to charge seven or eight hundred pounds for doing this, while referring to the process as "chipping" and even telling their customers that the ECU has indeed been remapped - although this would be pointless because the MAC01 does not control either boost or fuel.

The effect of the Zener diode modification is to clamp the maximum boost level seen by the ECU to around 1.35 bar - the fuel pump cut-out function is disabled. Severe engine problems can be expected if the wastegate diaphragm tears, if the wastegate control hose splits, or if the fueling is inadequate for the boost levels being run. Note that the dashboard boost gauge - already an inaccurate device - will reflect the boost as seen by the ECU and not the actual boost level. This provides the best method for detecting a modified ECU:

- Detach the hose to the ECU from the inlet manifold.

- Attach a bicycle or similar pump with a pressure gauge to the hose.

- Turn on the ignition - it is not necessary to start the engine.

- Pump up the system until the external pressure gauge indicates 1 bar or 14.5 psi relative pressure, i.e., 2 bar absolute pressure.

- Compare with the dashboard pressure gauge. A significant discrepancy indicates a modified ECU.

- To test whether the fuel pump cut-off has been disabled, start the engine, raise the rpm above 3000 and repeat the test. The fuel pump should cut out.

- Remove the wastegate cap (CARE - spring loaded) and check the wastegate spring for the stock salmon-pink paint marks.

Robert Houk's pioneering work

RDH - as he is normally known - gave up messing with quattros many years ago. But his famous ur-quattro tuning page is still online.

MAC05 Replacement

The MAC05 fitted to early Type 44s is very similar electrically to the MAC01/MAC02 and uses the same connector. Adapting the loom is fairly easy. The benefit is that the MAC05 stores fault codes - a MAC05 conversion gives a WR ur-quattro similar diagnostic capabilities to the MB.

Back to ur-quattro Wiring Index

Contact Phil Payne by email or use mobile/SMS 07833 654800