Engines without hydraulic tappets

- Clearance is checked and adjusted with the engine warm (coolant above 35°C - cylinder head warm)

Specified settings:

Inlet valves 0.20 to 0.30 mm

Exhaust valves 0.40 to 0.50 mm

(Try to set to the mean value)

It is not always possible to measure the tappets with the engine warm, e.g., if it has already been dismantled and it is desired to reassemble it it correctly:

Cold tappet worksheet

- Turn crankshaft until cams of cylinder to be set are pointing upwards uniformly

- Check clearance between camshaft and bucket tappet

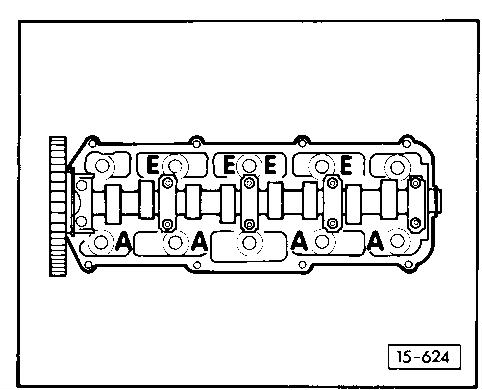

e.g. on 4 cylinder engine

- A - exhaust valve

- E = inlet valve

Shims are available in thicknesses from 3.00 to 4.52 mm in steps of 0.05 mm. The marking on the shim must face downwards, i.e., into the bucket

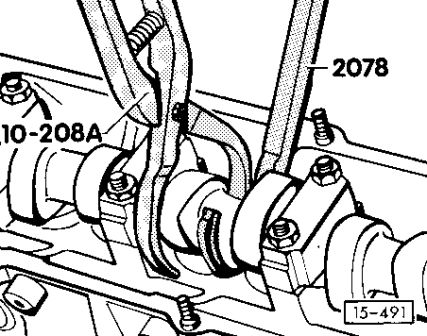

- Press the tappet down with 2078

- Remove shim with pliers 10-208A

- Insert shim of required thickness. Used shims can be reinstalled provided they are undamaged

- Install a new cylinder head cover gasket and rubber seal on camshaft bearing cap #1