The UK quattro Network

The UK's mobile Audi 5-cylinder mechanic - 07833 654800, 24x7

Specialist in turbos, quattros, electrics and non-starts

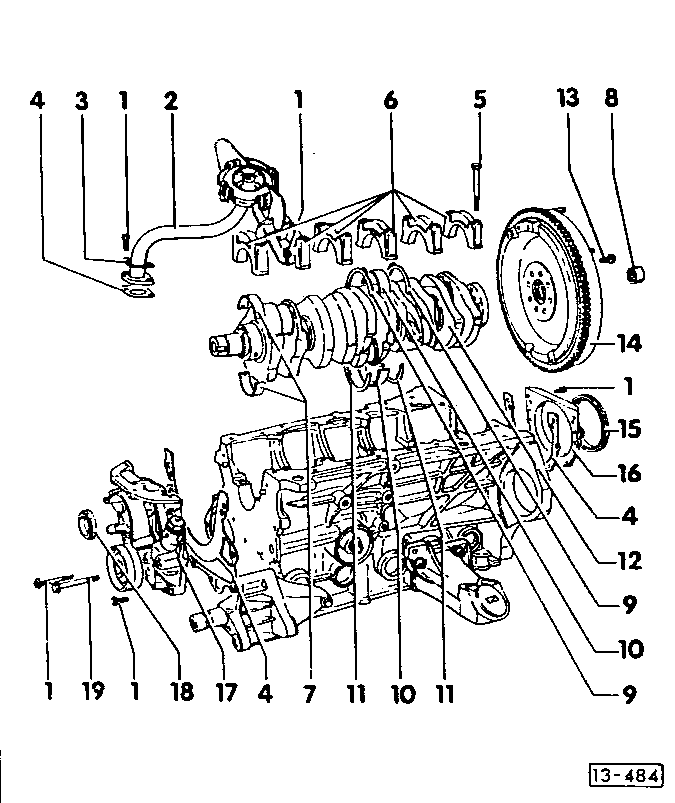

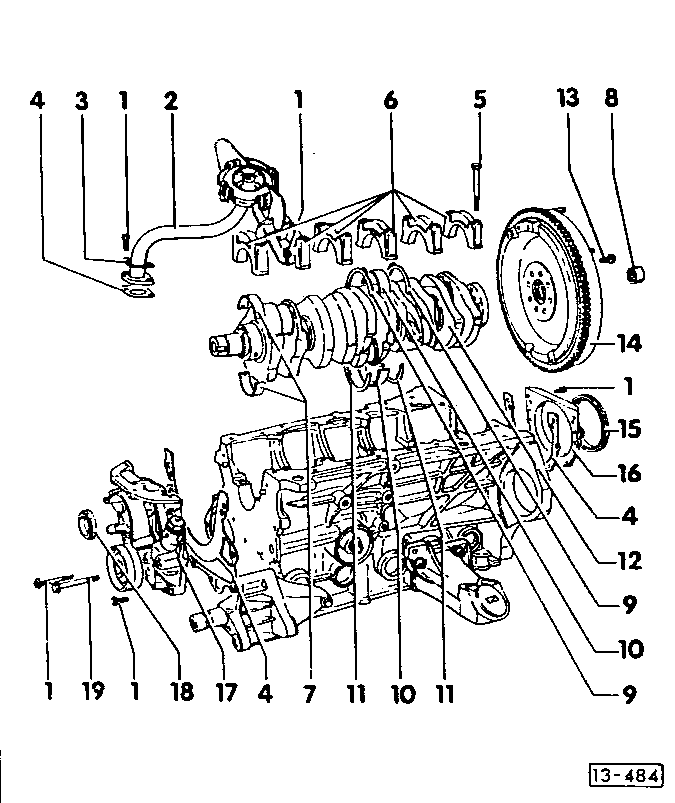

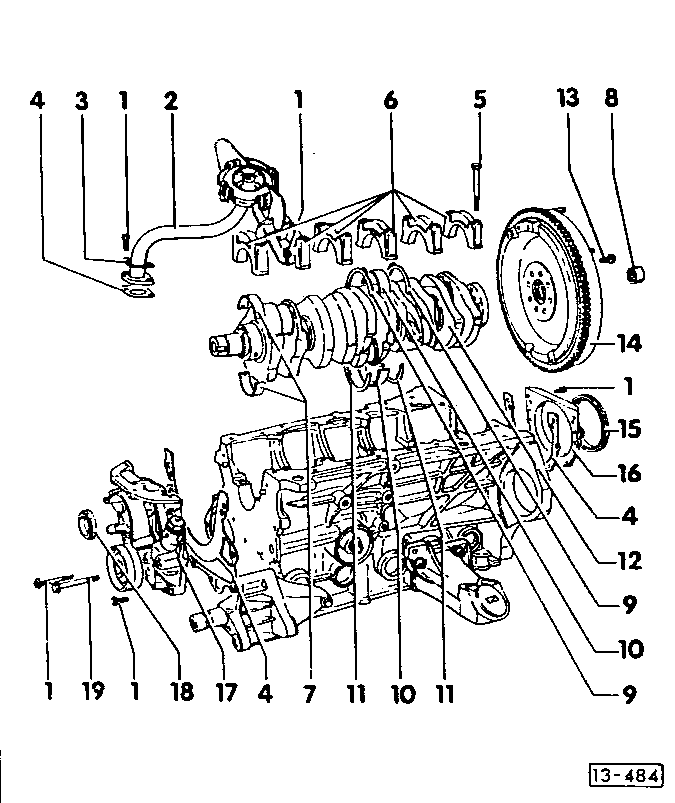

Crankshaft Group - Dismantling the Cylinder Block, Crankshaft and Flywheel

Note - the engine is pictured upside-down.

- 10Nm bolts. If a torque wrench is used,it should be within its calibration period. If the front oil pump retaining bolts are sheared, the engine may need to be removed from the vehicle.

- Oil pump pickup pipe

- Locking plate (tab washer) - always renew.

- Gaskets. Now that Audi ship 15 and 16 as a unit, a second rear oil seal gasket is the only way to move the lip of the oil seal away from wear grooves on the rear of the crankshaft.

- Observe main bearing torque.

- Main bearing caps:

- Number 1 bearing cap at the pulley end.

- Retainging lugs on bearing caps must be in line.

- Note offset bores.

- Main bearing shells 1 2 3 5 & 6:

- Shell with oil feed groove to block side of bearing.

- Shell without oil groove fits into cap.

- Change shells per bearing only as pairs.

- If present, retaining lug must engage in recess in cylinder block or bearing cap. Note - more modern bearings have no such recesses but can be used without problems.

- Needle roller:

- The needle roller is part of the crankshaft and comes fitted in both a new crankshaft or a new short engine.

- Although various techniques have been documented (slide hammer inner bearing remover, grease packing, etc.) the only consistently successful technique is to collapse the bearing in on itself by skillful use of a small cold chisel.

- When refitting, the inscription faces outwards.

- Thrust washers for cap - note fixing.

- Bearing shell 4

- Thrust washers for block

- Crankshaft

- Flywheel bolts should always be replaced. They come in two forms - with and without shoukders. Consult the correct torque settings.

- Flywheel timing pegs.

- Oil seal. No longer available separately - shipped with the flange below.

- Oil seal flange. In instances of severe crankshaft wear, it may be advisable to fit two gaskets so as to shift the lip of the seal away from a groove on the crankshaft. New seals must always be oiled before assembly.

- Oil pump. Driven by a cross-shaped dog clutch on the crankshaft - take care with alignment when reassembling.

- The crankshaft oil seal is fitted during manufacture with a small gap at the rear. If there are traces of wear on the crankshaft, the new seal should be pressed fully home to act on an unworn section of the shaft. Again, shaft oil seals should be lightly oiled before assembly.

Back to index

Next page

Kerbside Motors Home Page and Contact Information